Getting the Analytical Method Validation, Verification and Transfer Right

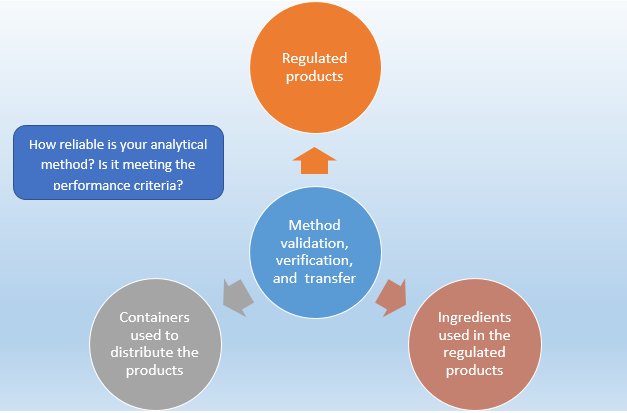

The FDA requires that the testing of regulated products such as Pharmaceuticals, medical devices, cosmetics, and Dietary supplements must satisfy certain performance criteria. If the test results fail to meet the performance criteria, the FDA does not accept the products. A method validation is performed to determine the reliability of an analytical method. Method validation, method verification, and method transfer not only applies to testing of regulated products but also applies to the ingredients used in the manufacture of the product and the containers that are used to distribute the products.

To get the correct analytical results, it is important to use the accurate standards or (certified) reference materials. Regardless of how skilled the analysts are or how sophisticated and automated the equipment is, if the calibration of the system is incorrect, the analytical result will always be wrong. You should implement practical approaches to the selection, purchasing, testing, storage and use of (certified) reference material.

Many in the regulated environments do not have a clear understanding about Method validation, method verification and method transfer. A clear understanding is crucial because reliable analytical results are essential to make an informed decision about the quality and safety of the products in the pharmaceutical industry. Also, such analytical data are required for regulatory submissions to support the drug product registrations.

Understanding Method Validation

'Analytical method validation is the process of demonstrating that an analytical procedure is suitable for its intended purpose.'

USP General Chapter <1225> provides specific details about method validation. Taking a deep dive into its final version and FDA guidance for conducting and documenting method transfer between laboratories and sites will be invaluable to your organization.

'Although not all of the validation characteristics are applicable for all types of tests, typical validation characteristics are:

- Specificity

- Linearity

- Accuracy

- Precision (repeatability, intermediate precision, and reproducibility)

- Range

- Quantitation limit

- Quantitation limit.'

'Specificity: Specificity is the ability to assess unequivocally the target pathogen or analyte in the presence of components which might be expected to be present.

Linearity is the ability of the assay to return values that are directly proportional to the concentration of the target pathogen or analyte in the sample.

Accuracy is the agreement between value found and an excepted reference value

Precision is the variability in the data from replicate determinations of the same homogeneous sample under the normal assay conditions

Range is the concentrations of analyte or assay values between the low and high limits of quantitation.

Ruggedness is the reproducibility of the assay under a variety of normal, but variable, test conditions Quantitation limit: Characteristic of quantitative assays for low levels of compounds in sample matrices

Robustness is a measure of the assay capacity to remain unaffected by small but deliberate changes in test conditions' - Source Assay Validation Methods - Definitions and Terms as Adapted from Dr. Robert Mandle, BioSciences Research Associates, Inc.

Method validation is required in the following situations:

- The Method transfer to the different laboratory

- Before the use of the method in ongoing or routine testing

- When there are changes to previously-validated conditions or method parameters, if changes extend beyond the scope intended by the original method

- Method is part of a New Drug Application (NDA) or Abbreviated New Drug Application (ANDA) submission

Method validation is often cited in FDA inspectional observations, Warning Letter violations and reviewer comments regarding NDA and ANDA submissions. Even if the compendia method is used unchanged, its suitability for the finished product in question should be demonstrated.

All pharmaceutical analytical chemists and supervisors responsible for validating new or modified analytical methods, and the personnel responsible for hosting FDA inspections, responding to 483s and Warning Letters or preparing NDAs or ANDAs must understand the analytical best practices for method validation.

Is it required to validate USP Methods

As the USP methods are successfully validated before their inclusion within the USP, they generally are not required to be validated. However, they only need the suitability test. The exact procedure including the mobile phase and all parameters described in the monograph should be followed through.

Understanding Method Verification

Method verification defined: 'Establishing documented evidence which provides a high degree of assurance that a specific process will consistently produce a product meeting its predetermined specifications and quality attributes.' - U.S. FDA

Method verification is synonymous with single-laboratory validation. It is conducted when a laboratory uses a method for the first time. It is also conducted when a particular aspect of a method or its implementation is changed. For instance, when there is a new analyst, a new equipment or equipment part, new batch of reagent, changes in the laboratory premises etc.

The minimum verification is required to analyze the material prior to and post the change to check the consistency of the results in terms of mean and standard deviation.

The basic experiments that should be performed to verify the use of a standard method prior to its first use in a laboratory include:

- Bias recovery

- Precision

- Measurement uncertainty

- Calibration model

- Limit of detection

Understanding Method Transfer

'The transfer of an analytical method is defined as the documented process that qualifies a laboratory (receiving laboratory) to use an analytical method that originated in another laboratory (transferring laboratory), whether that is internal or external to the receiving laboratory.' - USP

The types of method transfer are:

- Comparative testing

- Co-validation between two or more laboratories

- Revalidation or partial validation

- Analytical method transfer waiver

Of the performance analytics that should be challenged, the following are the major ones.

- System Stability

- Precision

- Intermediate Precision

- Regularity

- Limits of Detection (LOD)

- Limits of Quantification (LOQ)

- Specificity

- Solution Stability

The desired results of the analytical method transfer form the basis for the selection of categories for performance analytics. Prior to conducting the method transfers, they should be defined and must have the pre-approved protocol. The pre-defined protocol must consist of the following:

- Clearly defined objectives

- List of the necessary materials

- The analytical procedures to be transferred from the original to receiving site

- The acceptance of the material which it will be assessed against

After the executing the method transfer, the receiving laboratory and the transferring laboratory should create and approve the report of the summary in writing.

There are recent changes in the guidance from regulatory agencies (FDA/EMA, USP and ICH) on method validation and transfer, integrated validation, verification and validation of analytical procedures for equivalency testing and statistical evaluation. To ensure compliance, it is crucial to understand the changes.

Attend the seminar 'Analytical Method Validation, Verification and Transfer' to gain Guidance and advice based on interactions with the global pharmaceutical industry, FDA and other regulatory authorities worldwide.

Ms. Thomas has over two decades of cGMP hands-on industry experience in both pharmaceutical and medical device manufacturing operations. Her experience covers all Quality Systems; as well as, all areas of validation; including, process/product validation, facilities validation, CSV and 21 CFR Part 11, test method validation, equipment/automated processes and cleaning validation. Utilizing strategic thinking, risk-based approaches, and Lean principles, she has demonstrated success in steering and managing complex projects within the pharmaceutical and medical device industries.

FAQs on Analytical Method Validation and Verification

1. What is analytical method validation and why is it important?

Analytical method validation is the process of proving that a testing method is reliable, accurate, and suitable for its intended purpose. It’s important because regulatory agencies like the FDA, USP, and ICH require proof that your lab methods can consistently generate trustworthy data. In short, no validated method → no credible results → no regulatory compliance.

2. What is the difference between method validation and method verification?

Method validation is a full qualification of a non-compendial method—usually developed in-house. Method verification is a simplified check to confirm you can run a compendial method (like USP or EP) in your own lab, under your own conditions. Verification is less extensive but still critical to demonstrate suitability.

3. When is method transfer required in a regulated industry?

Method transfer is required whenever a validated method moves from one laboratory to another—for example, from R&D to QC, from a sponsor to a CRO, or between manufacturing sites. The goal is to ensure the receiving lab can perform the method with equivalent accuracy and precision. Regulators expect documented evidence of successful transfer.

4. What are the key parameters evaluated during method validation?

Common validation characteristics include:

- Accuracy

- Precision (repeatability & intermediate precision)

- Specificity

- Linearity

- Range

- Detection and quantitation limits

- Robustness

These parameters help build confidence that your method performs consistently across its entire intended use.

5. What issues commonly cause method validation failures?

Frequent causes include poor method development, inadequate sample preparation, unoptimized instrument parameters, and environmental variability. Inadequate analyst training and incomplete documentation are also major contributors. Fixing these early prevents delays and revalidation.

6. How do FDA, USP, and ICH guidelines differ in their validation expectations?

All three emphasize the same core principles, but:

- ICH Q2(R1)/Q2(R2) provides the most detailed international guideline.

- USP <1225> focuses specifically on analytical procedure validation.

- FDA guidance aligns closely but adds clarity on lifecycle, documentation, and GMP expectations.

Together, they form a consistent global framework labs must follow.

7. What is the recommended approach to successfully transfer an analytical method?

A smooth method transfer typically involves:

- A detailed method review

- A predefined transfer protocol

- Side-by-side testing or comparative analysis

- Statistical evaluation of equivalence

- Clear pass/fail criteria

- Joint documentation between both labs

Communication between sending and receiving labs is often the make-or-break factor.

8. How does method robustness affect method validation?

Robustness shows how well a method performs when small, deliberate variations are introduced—such as slight temperature changes, pH shifts, or flow rate differences. A robust method reduces out-of-spec results, minimizes investigations, and increases long-term reliability.

9. Does every analytical method need complete revalidation after changes?

Not always. Minor adjustments may only require partial validation or verification, depending on how much the change affects method performance. Regulatory expectations recommend using a risk-based approach to determine the level of revalidation needed.

10. What documentation is required to support analytical method validation?

Typical documentation includes:

- Validation protocol

- Raw data & chromatograms/spectra

- Statistical evaluations

- Deviations, investigations & justifications

- Validation report

Clear, traceable documentation is essential for audits and regulatory submissions.