RoHS and REACH - Compliance Requirements and Differences between the two

If you are a manufacturer, importer, or a distributor, of electrical and electronic equipment (EEE) placing products on the UK market, understanding ROHS and REACH compliance is vital. Compliance protects your products from stop shipments and fines. It helps meet the requirements of customers and governments globally. It also minimizes waste, scrap, and rework, enhances the brand and fosters your alignment with suppliers.

What are the compliance RoHS and REACH requirements? What are the differences between them? What steps should you take to comply? This article explains.

Understanding RoHS

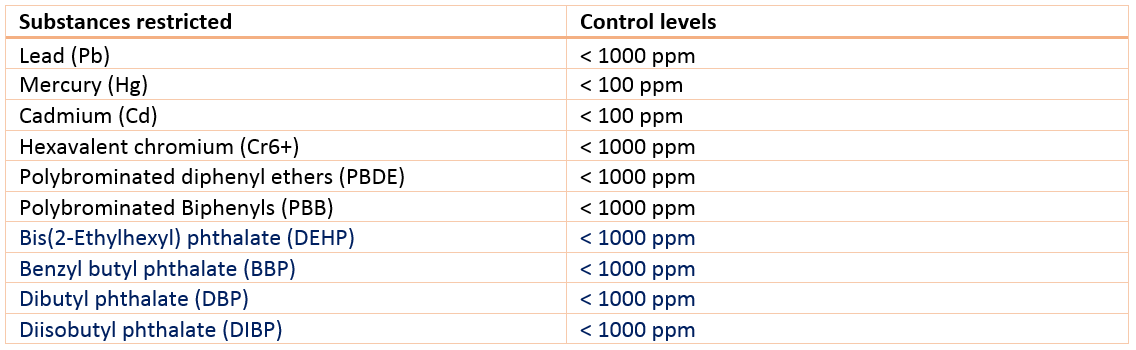

RoHS stands for Restriction of Hazardous Substances. It is an 'EU legislation restricting the use of hazardous substances in EEE and promoting the collection and recycling of such equipment.' The directive which is in force since 2003, also supports effective recovery, reuse, and recycling of products. The energy-consuming products are regulated to control the level of hazardous substances they contain:

The first six applied to the original RoHS while the last four were added under RoHS 3.

Concerned Equipment

- Large household appliances (LHA)

- Small household appliances (SHA)

- IT and telecommunications equipment

- Consumer equipment

- Lighting equipment

- Electrical and electronic tools

- Toys, leisure, and sports equipment

- Medical devices

- Monitoring and control instruments

Products that are deemed specifically out of the scope of the ROHS directive are:

- Products for military use or designed to be sent into space

- Products designed to be sent into space

- Equipment specifically designed and is to be installed as part of another type of equipment

- Large-scale industrial tools and fixed installations

- Large-scale stationary industrial tools

- Means of transport (apart from certain two-wheeled electric vehicles)

- Non-road mobile machinery for professional use

- Products for research and development available on a business-to-business basis

- Active implantable medical devices

RoHS Compliance:

To comply with RoHs, all products you place on the UK market must:

- Have a current declaration of the technical file

- Have a declaration of conformity

- Be marked relevantly

- Display the CE label

Use the following checklist to determine if your products are RoHS compliant:

- Do my components and subassemblies of EEE contain less than the maximum prescribed levels of lead (Pb), mercury (Hg), cadmium (Cd), hexavalent chromium (CrVI), polybrominated biphenyls (PBB), polybrominated diphenyl ethers (PBDE), and four different phthalates (DEHP, BBP, BBP, DIBP)?

- Do I evaluate and self-certify my production controls with reference to the measures detailed in the regulations?

- Do my products have a Declaration of conformity supported by a technical file that shows compliance?

- Are the Declaration of conformity readily available to be provided to the Office for Product Safety and Standards (Safety & Standards) if asked for?

- Am I aware that the Declaration of conformity and technical file must be retained for 10 years after the EEE is first placed on the UK market?

- Do my individual products have a type, batch or serial number showing the manufacturer's name, address and registered trade name or mark?

- Do my products display the CE label?

- If I am an importer placing EEE on the UK market under my name or trademark, does the product comply with all the obligations on the manufacturers?

- If I am a distributor, does the EEE I distribute marked appropriately and display the CE label?

- If I am a distributor who modifies the product before distribution, does it comply with all the obligations on manufacturers?

What to do if the product is discovered or suspected to be non-compliant?

Specific steps must be taken:

- Notify Market Surveillance Authority (MSAs). The RoHS notification guidance and form for completion is here.

- Notify the supply chain

- Manufacturers and importers must notify their distributors

- Importers must notify the manufacturer

- Distributors must notify the importer or manufacturers as relevant

- Take action to remediate the problem

- Quarantine the product

- Fix the non-conformity

- Suspend it from being made available to the supply chain and end users

- Recall it from end users

- Keep a register of non-conformities and maintain it for 10 years

Useful resources

RoHS Regulations 2012 - The Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment Regulations 2012 RoHS guidance RoHS (European Commission)

Understanding REACH

REACH stands for Registration, Evaluation, Authorisation, and Restriction of Chemicals. It is a regulation of the European Union.

- Regulation number 1907/2006

- Concerns chemicals and their safe use

- Has a defined process that must be followed for risk and chemical management

- New substances are added to the candidate list every 6-9 month

- Proposed SVHCs (Substance of very high concern) are put to a 45-day public comment

What is covered?

- Human and veterinary medicines

- Food and foodstuff additives

- Plant protection products and biocides

Other substances that have tailored provisions as long as they are used in specified conditions

- Isolated intermediates

- Substances used for research and development

Restricted list

- Companies must ensure restricted substances in products do not exceed REACH thresholds

- 69 valid entries on REACH Annex XVII (updated on 17 Oct 2018) on the list of SVHCs available for restricted use

Additional hazardous substances on REACH annex XVII include:

- Azocolourants and Azodyes (entry 43)

- Polycyclic-aromatic hydrocarbons (PAHs) (entry 50)

- Perfluorooctane sulfonic acid and its derivatives (PFOS) (entry 53, deleted in 2010 and subject to EU POPs regulation now.)

- Pthalates (entry 51 and 52)

- Cadmium and its compounds (entry 23)

- Nickel and its compounds (entry 27)

- Lead and its compounds (entry 63)

- Mercury and its compounds (entry

- Chromium VI compounds (entry 47)

- Arsenic compounds (entry 19)

- CMR 1A/1B substances listed in the annex VI of CLP regulation (28, 29, 30)

- Nonylphenol and nonylphenol ethoxylates (entry 46)

- Organostannic compounds (entry 20)

- Hazardous solvents (benzene, cyclohexane,triclorobenzene, chloroform, etc);

- Bisphenol A (entry 66, added in Dec 2016)

- decaBDE (entry 67, added in Feb 2017)

- PFOA, its salts and PFOA-related substances (entry 68, added in June 2017)

- D4 and D5 (entry 70, added in Jan 2018)

- Methanol (entry 69, added in April 2018)

- 1-methyl-2-pyrrolidone(NMP) (entry 71, added in April 2018)

- CMR substance in textile and footwear (entry 72, added in Oct 2018)

Who is responsible for compliance?

- Manufacturers of substances

- Importers who buy chemicals, raw materials from outside the EEA

- Distributors who store and distribute chemicals and/or finished products

- The representative who represents a non-EEA company selling chemicals and/or goods to the EEA

- Manufacturer outside the EEA

- Trader of very hazardous chemicals

- Biocides supplier or user

- The user of chemicals who mixes and uses them in industrial or professional activities

Compliance depends on the type of products you place on the market or use.

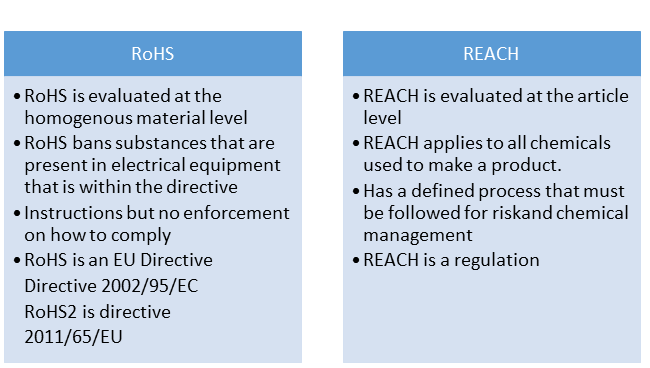

RoHS and REACH are two critical regulations that play a vital role in protecting human health and the environment from the risks associated with hazardous substances. While both regulations share common goals, they differ significantly in scope, application, and compliance requirements. Companies must navigate the complexities of these regulations to ensure that their products meet the necessary standards and can be legally sold in the EU market.

Difference between RoHS and REACH

While both RoHS and REACH aim to protect human health and the environment, they differ significantly in scope, application, and compliance requirements.

Scope of Application

- RoHS: RoHS is limited to electrical and electronic equipment (EEE). It focuses on restricting specific hazardous substances in these products to reduce electronic waste's environmental impact.

- REACH: REACH has a much broader scope, covering all chemical substances, regardless of their application. This includes substances used in industrial processes, consumer products, and even those present in articles such as furniture, clothing, and toys.

Restricted Substances

- RoHS: RoHS restricts ten specific hazardous substances in EEE. These substances are primarily heavy metals and flame retardants, which pose significant environmental and health risks when improperly disposed of.

- REACH: REACH addresses a broader range of hazardous substances, including those classified as Substances of Very High Concern (SVHC). These substances may include carcinogens, mutagens, reproductive toxins, and those that are persistent and bioaccumulative.

Compliance Requirements

- RoHS: Compliance with RoHS involves ensuring that restricted substances are not present in EEE above the specified concentration limits. This typically requires material analysis, product testing, and maintaining documentation to demonstrate compliance.

- REACH: REACH compliance is more complex and involves multiple steps, including registration, evaluation, authorization, and restriction. Companies must submit detailed information about the substances they use, assess risks, and obtain authorization for certain substances.

Geographic Application

- RoHS: RoHS is primarily an EU directive, but similar regulations have been adopted in other regions, such as China, Japan, and the United States, with varying requirements and scope.

- REACH: REACH is also an EU regulation but has a broader impact, as it applies to any company that produces, imports, or uses chemical substances within the EU. Non-EU companies that export products to the EU must also comply with REACH.

CE Marking

- RoHS: Products that comply with RoHS must carry the CE marking, indicating that they meet EU safety, health, and environmental protection standards. The CE marking is mandatory for EEE sold in the European Economic Area (EEA).

- REACH: REACH does not require CE marking. However, compliance with REACH is essential for products to be legally placed on the EU market.

Challenges in Achieving RoHS and REACH Compliance

Compliance with both RoHS and REACH presents significant challenges for businesses, particularly those that operate in multiple markets or rely on complex supply chains.

Supply Chain Complexity

- One of the primary challenges is managing the complexity of global supply chains. Companies must ensure that all components and materials used in their products comply with RoHS and REACH requirements. This involves working closely with suppliers, conducting material analysis, and maintaining accurate records.

Continuous Monitoring and Updates

- Both RoHS and REACH regulations are subject to periodic updates, with new substances added to the restricted or SVHC lists. Companies must continuously monitor these updates and adjust their compliance efforts accordingly. Failure to do so can result in significant penalties and disruptions to market access.

Cost Implications

- Achieving compliance with RoHS and REACH can be costly, particularly for small and medium-sized enterprises (SMEs). The costs associated with testing, material analysis, registration, and documentation can add up quickly. Additionally, companies may need to invest in new technologies or redesign products to eliminate or reduce the use of hazardous substances.

Knowledge and Expertise

- Navigating the complexities of RoHS and REACH requires specialized knowledge and expertise. Companies must stay informed about regulatory developments, understand the technical requirements, and implement effective compliance strategies. This may require hiring or training staff, consulting with experts, or collaborating with industry associations.

Benefits of RoHS and REACH Compliance

Despite the challenges, compliance with RoHS and REACH offers several benefits for businesses and society as a whole.

Market Access

- Compliance with RoHS and REACH is essential for companies that want to access the EU market. Meeting these requirements ensures that products can be legally sold in the EU, avoiding costly delays, fines, and potential bans.

Enhanced Brand Reputation

- Companies that demonstrate a commitment to environmental protection and human health through RoHS and REACH compliance can enhance their brand reputation. Consumers are increasingly aware of the environmental and health impacts of products, and they are more likely to support companies that prioritize sustainability.

Risk Reduction

- By eliminating or reducing the use of hazardous substances, companies can minimize the risks associated with chemical exposure, both for workers and consumers. This can lead to improved safety, reduced liability, and a lower risk of regulatory penalties.

Innovation and Competitiveness

- Achieving RoHS and REACH compliance often requires companies to innovate, whether by finding alternative materials, redesigning products, or improving manufacturing processes. These innovations can lead to competitive advantages, such as improved product performance, reduced costs, and access to new markets.

Attend the seminar Understanding REACH and RoHS Compliance & Protecting Revenues with Advanced Compliance to gain a deeper understanding of the specifics of REACH and RoHS regulations, examine case studies and learn from the mistakes of others. The seminar will draw out key developments and key dates (if applicable) with particular emphasis on requirements for US firms.

The course instructor Ms. Eisenhardt has over 20 years of experience in IT and Compliance Software Development, her former roles include: Executive Director of Environmental Programs, at Fair Factories Clearinghouse; Environmental Compliance Manager and Design for Environment programs at EMC Corporation; and Director of Product Management at PTC Corporation for Windchill Product Analytics - an environmental compliance software.

FAQs on RoHS and REACH - Compliance

1. Why is RoHS and REACH compliance important for manufacturers and importers?

Compliance ensures your products can legally enter the EU and UK markets, protects your brand reputation, and reduces the risk of environmental fines or recalls. Non-compliance can lead to:

- Product bans or import refusals

- Heavy financial penalties

- Damage to customer trust and supply chain relationships

Beyond regulation, RoHS and REACH compliance demonstrates your company’s commitment to sustainability and corporate responsibility — a growing expectation among global buyers.

2. How can a company achieve RoHS and REACH compliance?

Compliance involves:

- Supply Chain Communication – Obtain compliance declarations and material data from suppliers.

- Material Testing & Documentation – Conduct lab analysis or XRF screening to verify substance content.

- Risk Assessment – Identify and prioritize materials at risk of containing restricted substances.

- Technical Documentation (DoC) – Maintain a Declaration of Conformity and supporting test reports.

- Continuous Monitoring – Stay updated with regulation revisions and SVHC list updates. Many companies use compliance software or third-party audits to simplify this process.

3. What is a Declaration of Conformity (DoC) in RoHS?

A Declaration of Conformity is an official document that certifies a product meets all relevant RoHS requirements. It typically includes:

- Manufacturer/importer details

- Product identification

- Reference to applicable RoHS directives

- Signature and date of declaration

The DoC must be available to market surveillance authorities upon request and updated whenever the product design or regulation changes.

4. Does REACH compliance apply to products outside the EU?

Yes — any company exporting to the EU (even if located outside of it) must comply with REACH if their products contain chemical substances above certain thresholds. Non-EU manufacturers often appoint an Only Representative (OR) within the EU to handle registration and compliance duties.

5. What happens if a product fails RoHS or REACH compliance testing?

If a product is found non-compliant, manufacturers may face:

- Product recalls or shipment holds

- Re-testing and re-certification costs

- Potential bans from EU markets

- Damage to brand credibility

It’s best to perform proactive internal audits and work closely with accredited testing laboratories to avoid compliance failures.

6. How often do RoHS and REACH regulations change?

Both frameworks are living regulations that evolve based on new scientific data and environmental policy goals.

- RoHS updates occur every few years (e.g., new substance additions like phthalates in RoHS 3).

- REACH updates happen multiple times per year, especially as new SVHCs are added. Subscribing to official EU notifications or using a compliance monitoring service ensures you remain ahead of changes.

It’s best to perform proactive internal audits and work closely with accredited testing laboratories to avoid compliance failures.

7. Can one compliance certificate cover both RoHS and REACH?

No — RoHS and REACH are separate legal frameworks with distinct scopes and requirements. However, many companies combine their documentation into an integrated compliance statement to simplify supplier communication and audits.

8. How can RoHS and REACH compliance improve brand value and sustainability?

Demonstrating compliance signals that your organization prioritizes environmental protection, human safety, and ethical sourcing. It builds trust with eco-conscious consumers, global partners, and regulatory bodies — ultimately strengthening your ESG profile and competitive edge in international markets.